CNC turning center ST25L / ST25LM

CNC turning center ST25 series is the joint development of the “StankoMashStroy” company and the Korean company SMEC. Machine doesn‘t have analogs at the Russian market.

| Parameters | ST25L | ST25LM | |

|---|---|---|---|

| Maximum swing over bed | mm | Ø520 | Ø650 |

| Maximum swing | mm | Ø380 | Ø380 |

| Maximum length of the workpiece | mm | 1030 | 1020 |

| Travel X/Z axis | mm | 200/1090 | 225/1040 |

| Spindle: | |||

| Spindle speed | rpm | 35-3500 | 35-3500 |

| Spindle nose | JIS A2-8 | JIS A2-8 | |

| Bore diameter | mm | Ø86 | Ø86 |

| Spindle indexing | degree | - | 0.001 |

| Inner diameter of front bearing | mm | 130 | 130 |

| Turret: | |||

| Number of tool positions | 10/12 (opt.) | 12 (BMT 65) | |

| Turning tool shank size | mm | 25 | 25 |

| Boring bar size | mm | Ø40 (50) | Ø40 (50) |

| Rotary tool maximum speed | rpm | - | 50-5000 |

| Clamping force | kgf | 2905 | 3955 |

| Feed: | |||

| Rapid traverse X/Z | mm/min | 18000/24000 | 18000/24000 |

| Cutting feed X/Z | mm | 0.0003-285/0.0003-357 | |

| Tailstock: | |||

| Tailstock travel | mm | 990 | 1020 |

| Quill diameter | mm | 110 | 110 |

| Taper | MT5 | MT5 | |

| Quill travel | mm | 100 | 100 |

| Motors: | |||

| Main motor | kW | 18.5/22 | 18.5/22 |

| Servo motor | kW | 3 | 3 |

| Hydraulic system motor | kW | 1.5 | 1.5 |

| Lubrication motor | kW | 0.018 | 0.018 |

| Coolant motor | kW | 0.4 | 0.4 |

| Rotary tool motor power | kW | - | 2.2/3.7 (3.7/5.5) |

| Power requierements: | |||

| Maximum power consumption | kVA | 39 | 39 |

| Tank capacity: | |||

| Hydraulic tank capacity | l | 14 | 14 |

| Lubrication tank capacity | l | 1.8 | 1.8 |

| Coolant tank capacity | l | 256 | 256 |

| Dimensions: | |||

| Floor space [with chip conveyor] | mm | 3880 [4807] x 1617 | 3885 [4807] x 1705 |

| Machine weight | kg | 6200 | 6600 |

ST25 series machine with numerical program control can carry out complex machining by means of various tools. The turning center can be equipped with 12-position turret, and all 12 positions can be used for the driving tool simultaneously that significantly expands technological capabilities and increases labor productivity.

Bed

45-degree slant bed provides the sufficient strength and rigidity at the extreme loadings because of high-performance processing. The guideways carry high loads. Strength margin allows the ball screw works both in the high speeds, and in the mode of power turning.

The bed is cast from high-strength cast iron in Penza city. It naturally and artificially aged, has additional strengthening ribs and specially developed construction. Machining and hardening of guideways are made by the “StankoMashStroy” company.

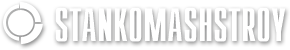

Turret

CNC turning center ST25LM is equipped with BMT65 turret made by South Korea and holders made by WTO company. Drive power is 2.2/3.7 kW standard or 3.7/5.5 kW optional. The main advantage of turret is the possibility to install all 12-drive holders simultaneously, turned the lathe into the milling center. The turret indexing accuracy is ±0,003 mm.

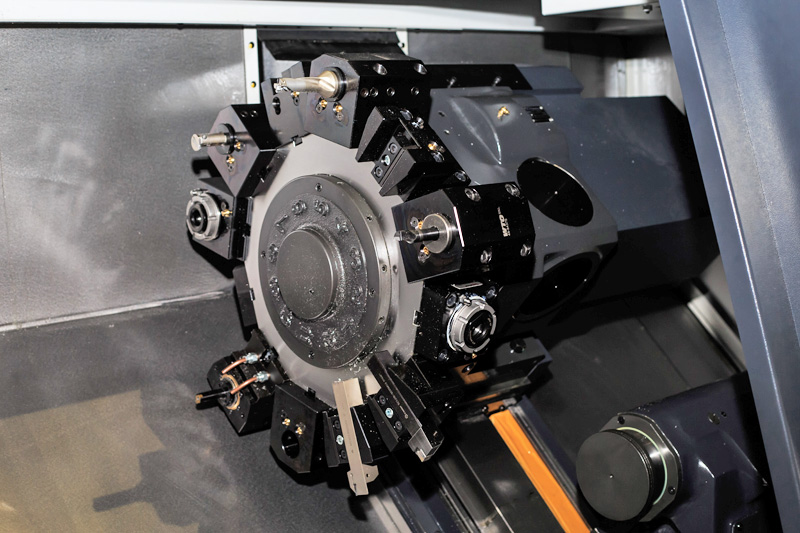

Spindle

Machining and assembly is made in the temperature-controlled rooms, equipped with precision SKF bearings. It has high output capability and high vibration strength that allows to machine alloy-treated steel and special alloy with 7 accuracy degree and degree of roughness 0.8 under Ra criterion.

Tailstock

Electric cabinet