ST 16k20

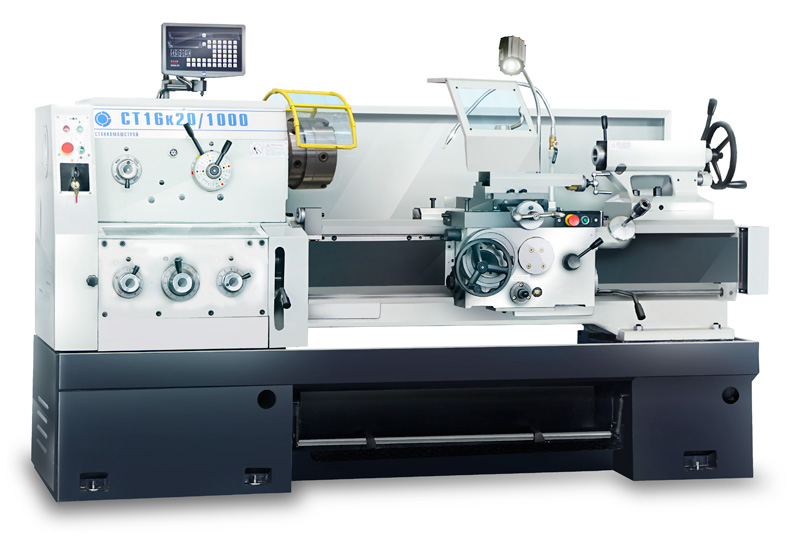

Lathes ST 16k20 series produced by StankoMashStroy are modern and upgraded analogues of Soviet lathe 16k20. The machines are rigid, accurate and reliable. Powerful spindle drive allows processing the workpiece of maximum length 750 mm and diameter up to 400 mm.

| Parameters | ST 16K20 | ||

|---|---|---|---|

| Maximum swing over bed | mm | Ø400 | |

| Maximum swing over cross-slide | mm | Ø220 | |

| Maximum length of the workpiece | mm | 750 | |

| Maximum turning length per one set | mm | 570 | |

| Bore diameter | mm | Ø52 | |

| Spindle taper | МТ. №6 | ||

| Spindle nose | ISO 702/III № 6 bayonet ring fixing type |

||

| Spindle speed | rpm | 9-1600 | |

| Number of speeds | 24 | ||

| Maximum spindle torque | Nm | 1400 | |

| Number and range of longitude feeds: | |||

| Standard | mm/rev (inch/rev) |

0.063-2.52 (0.0023-0.0937) | |

| Decreased | mm/rev (inch/rev) |

0.028-0.056 (0.0010-0.0021) | |

| Increased | mm/rev (inch/rev) |

2.86-6.43 (0.1064-0.2392) | |

| Number and range of cross feeds: | |||

| Standard | mm/rev (inch/rev) |

0.027-1.07 (0.0011-0.0404) | |

| Decreased | mm/rev (inch/rev) |

0.012-0.026 (0.0004-0.0010) | |

| Increased | mm/rev (inch/rev) |

1.21-2.73 (0.0457-0.1032) | |

| Number and range of threads: | |||

| Metric thread | mm | 0.5-224 | |

| Inch thread | 72-1/8 tpi | ||

| Module thread | 0.5-112 | ||

| Worm thread | 56-1/4 DP | ||

| Longitude rapid traverse | rpm | 4.5 | |

| Cross rapid traverse | m/min | 1.9 | |

| Thread pitch of the lead screw | mm | 12 | |

| Distance from the spindle to the tool base | mm | 28 | |

| Recommended size of the tool cross section | mm | 25х25 | |

| Compound rest angle | ° | ±90 | |

| Maximum travel of the longitude slide | mm | 145 | |

| Maximum travel of the carriage | mm | 320 | |

| Maximum cutting force | H | 12000 | |

| Maximum feeding force | H | 3500 | |

| Tailstock quill diameter | mm | Ø75 | |

| Tailstock quill taper | МТ№5 | ||

| Maximum travel of the tailstock quill | mm | 150 | |

| Cross travel of the tailstock | mm | ±15 | |

| Type of the main motor type | 5АМХ132S4У3 | ||

| Power of the main motor | kW | 7.5 | |

| Speed of the main motor | rpm | 1450 | |

| Type of the slide motor | 2AOS | ||

| Power of the slide motor | kW | 0.250 | |

| Speed of the slide motor | rpm | 1360 | |

| Type of the coolant pump | centrifugal | ||

| Type of the coolant pump motor | АИР56 А2у2 | ||

| Power of the coolant pump motor | kW | 0.180 | |

| Liquid flow at the end of the coolant pump | l/min | 25/32/50 | |

| V-belt | В-series | ||

| Machine dimensions (LхWхH) | mm | 2210х1020х1350 | |

| Machine net weight | kg | 2800 | |

| Parameters | ST 16K20 (with gap) | |

|---|---|---|

| Maximum swing over gap bed | mm | Ø630 |

| Operating area of gap bed | mm | 240 |

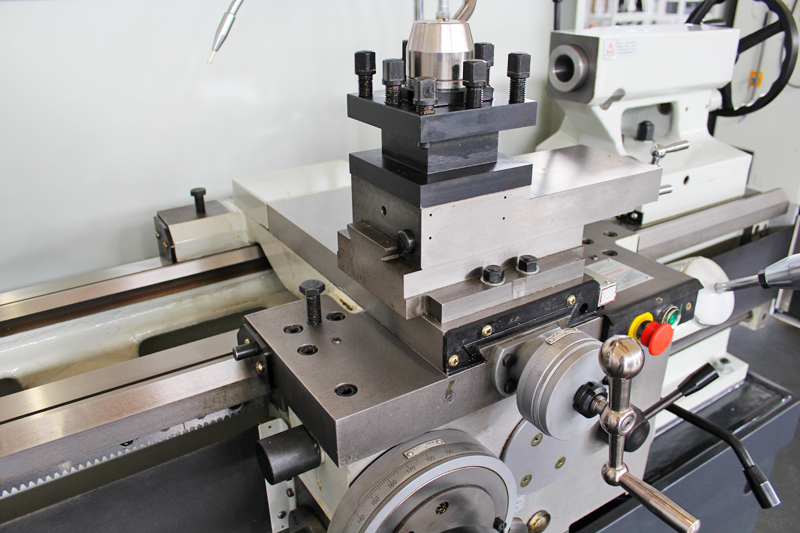

The machines are modern versions of 16k20 and 16k25 machines and can be applied in different branches of industry for various machining operations and different materials: outer and inner diameter machining; outer, inner, metric, inch, modular, worm threading; drilling, boring, reaming. Strong structure of the cast bed and its hardened precision-ground guideways provide professional machining and reliable stable work. Due to high-precision spindle bearings, the structure of the spindle unit and the whole machine is especially rigid. This allows heavy-duty machining, fully using the motor power. The machines are manufactured using advanced technology, they are easy to operate and keep precision for a long time. Hardened and precision-ground helical gears of the main spindle improve performance, insure quiet operation and long operating life of the machine and smoothness of gear shifting.

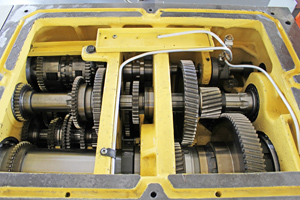

Gear Box

The gear box is used for reducing the speed of spindle rotation. It has 24 speed steps in the range from 9 to 1600 rpm. All the gears are heat-hardened, which increases their wear resistance. The lubrication system insures good cooling and fiction reduction, stabilizing errors caused by thermal deformation of the headstock during cutting.

- Standard accessories:

- Coolant supply system with a pump 25 l/min;

- Foot brake of spindle;

- Halogen light;

- Chuck safety guard;

- Splash guard;

- Installed drive belts, a set of 4 pcs;

- Lead screw protection and drive shaft protection, a set of 2 pcs;

- Tailstock;

- Adapter sleeve into spindle bore;

- Follow rest D20…80;

- Steady rest D20…125;

- Chuck adapter D250;

- 3-jaw chuck D250;

- Z axis adjustable stop;

- Dead center МТ5, for tailstock;

- Dead center МТ5, for adapter sleeve;

- Live center МТ5;

- 4-position tool holder;

- Hook spanner 45-52;

- Hook spanner 115-130;

- Hook spanner 150-160;

- Tool holder wrench;

- Adapter wrench;

- Operation manual (passport);

- Grease gun;

- Vibration mount ОВ-31М.

- Optional accessories:

- Coolant supply system with a pump 32 l/min;

- Coolant supply system with a pump 50 l/min;

- DRO for 2 axes with the screen, a set;

- Steady rest of a bigger diameter D120…220;

- Chuck adapter D315;

- Chuck adapter D400;

- Center chuck D250;

- 3-jaw chuck D315;

- 4-jaw chuck D400;

- Tool holder safety guard;

- Taper attachment ±10°;

- A set of soft solid jaws for 3-jaw chuck D250;

- A set of inside hard jaws for 3-jaw chuck D250;

- A set of outside hard jaws for 3-jaw chuck D250;

- A set of soft solid jaws for 3-jaw chuck D315;

- A set of inside hard jaws for 3-jaw chuck D315;

- A set of outside hard jaws for 3-jaw chuck D315;

- A set of universal jaws for 4-jaw chuck D400;

- Holder ECLNL 2525M12 or analogue;

- Insert СNMG 120408M-IW for holder ECLNL 2525M12 (divisible by 10);

- Insert СNMG 120404N-UZ for holder ECLNL 2525M12 (divisible by 10);

- Holder ECLNR 2525M12 or analogue;

- Insert СNMG 120408M-IW for holder ECLNR 2525M12 (divisible by 10);

- Insert СNMG 120404N-UZ for holder ECLNR 2525M12 (divisible by 10);

- Holder ETJNL 2525M16 or analogue;

- Insert TNMG 160408N-IW for holder ETJNL 2525M16 (divisible by 10);

- Insert TNMG 160404N-IW for holder ETJNL 2525M16 (divisible by 10);

- Holder ETJNR 2525M16 or analogue;

- Insert TNMG 160408N-IW for holder ETJNR 2525M16 (divisible by 10);

- Insert TNMG 160404N-IW for holder ETJNR 2525M16 (divisible by 10);

- Holder EWLNL 2525M08 or analogue;

- Insert WNMG 080408N-IW for holder EWLNL 2525M08 (divisible by 10);

- Holder EWLNR 2525M08 or analogue;

- Insert WNMG 080408N-IW for holder EWLNR 2525M08 (divisible by 10);

- Additional set of drive belts, 4 pcs.